What types of jersey pattern printing are there?

What types of jersey pattern printing are there?

When you customize football uniforms and sportswear, you will face a variety of printing processes to choose from. Each printing process has its applicable scenarios, as well as different advantages and disadvantages. Different printing processes should be used according to the fabric of the clothing, the complexity of the pattern, and the number of colors of the pattern. Today, we will introduce screen printing, thermal sublimation, heat transfer, embroidery, digital direct printing...

1.Screen printing:

Screen printing is a process that uses a silk screen printing plate. It uses the basic principle that the mesh of the graphic part of the screen printing plate is permeable to ink, while the mesh of the non-graphic part is not permeable to ink.

Screen printing can be printed on the surface of various materials. Screen printing has the characteristics of large printing area, bright colors, and clear layers. The printing has no obvious glue feeling, and it also has the advantages of water resistance, sun resistance, and wash resistance.

The disadvantage is that complex patterns such as gradient, ink splashing, and tie-dyeing cannot be screen printed. It is generally suitable for large-area patterns of no more than six colors, and the construction period is long. It needs to be published, printed, and dried, and it usually takes 3-5 days to complete.

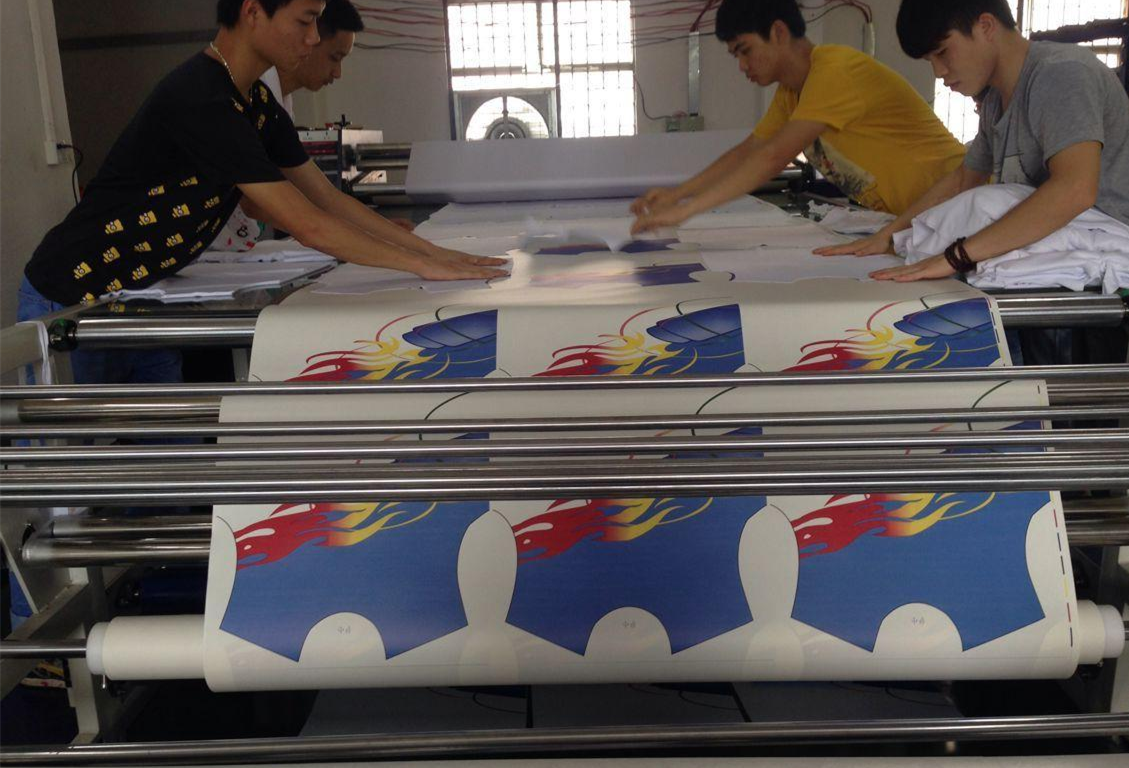

2. Thermal sublimation

Thermal sublimation is a transfer printing technology that uses high temperature to transfer the color pattern on the design to the clothing.

The pattern penetrates into the clothes, has no glue feeling, and feels good. Any pattern can be printed using this process. It has high water fastness and will not fade.

The disadvantage is that it is limited to fabrics. Pure cotton and dark clothes cannot be processed by this process. It can only be processed for white quick-drying, modal, imitation cotton and other fabrics.

The production period is very short and it can be shipped in 1-2 days.

3. Thermal transfer printing

Thermal transfer is a printing process using a thermal transfer machine. First, print the pattern on a PET film coated with a release agent. After drying, use this patterned film to heat the surface of clothes or other fabrics at high temperature and high pressure, leaving the pattern, tear off the waste film, and complete the heat transfer process. This method is called "heat transfer", also known as "heat transfer heat transfer". Basically, all clothes and all patterns can be processed by this process, and high-precision character photos and 3D game animation patterns and other colorful, layered, and delicate patterns can be printed. The finished product will be very close to the design draft, with small color difference and beautiful color. The disadvantages are high cost, a sense of glue at the printing position, and printing large pictures will affect the breathability of clothes. The printing period is 1-2 days.

4. Embroidery

Embroidery is a craft that uses an embroidery machine. It can be embroidered on the surface of most clothes,

but it is not recommended to embroider too thin clothes, which may cause the clothes to deform.

Embroidery is very strong, the pattern is uneven, and the three-dimensional sense is very strong,

but the cost is high, the limitations are large, and the construction period is long.

It usually takes 4-5 days to complete. Patterns with complex colors such as gradient, ink splashing,

and tie-dyeing cannot be done with this process.

5. Digital direct printing

Digital direct printing is a printing process that uses a digital printer to print the pattern you need directly on various materials. That is, the pattern to be printed is set by the computer and the machine prints it.

Digital direct printing uses inkjet printing, and the pigment enters the fabric when it is formed, breaking the limitations of general screen printing color overprinting and sudden color printing. Any picture can be printed.

The ink particles of digital printing are extremely fine, reaching the nanometer level, so they can easily penetrate into the fiber gaps of the fabric. They are both fast and do not affect the softness and comfort of the fabric itself. It can be printed on the surface of various materials, and the feel is the best when used on T-shirts.

Digital printing has the characteristics of fast printing speed, good printing effect, and water resistance. It also has the advantages of high flexibility and strong variability, and is suitable for small batch, personalized customization and other workwear orders. However, the cost is higher, the pattern is not as fine as hot stamping, and non-white clothes need to be sprayed with a layer of white base material first for digital direct printing, which will slightly affect the feel, and the construction period takes 2-4 days.

Thanks you visit our website, thank you interested our design.

Here it's Doris From Xiamen Junmao Technology Co., Ltd.

Thank you contact me,

We mainly engage in the production of sportswear, swimwear and accessories, with 13 years of production experience and a professional design team. We can perfectly produce your designs into products and also provide spot retail.

Samples order also support.

Custom logos, custom label, hang tag, packing... also be okay.

Stock design MOQ 30, mixed order also be okay, custom new styles MOQ 400 for each design.

Shipping usually 7-15 working days.

We have agents in many countries and often cooperate with national teams.

If you want some stock clothes, please contact us.

If you want that your design to become product, please talking with us.

If you want our catalog, or want more information, Please contact us.

Looking forward your reply.

Contact Way:

Doris yu

Sales Manager

Whatsapp: +8614700092670

E-mail: Dorisyu@junmaosports.com

Website:https://www.junmaosports.com/